Hearts of Oak

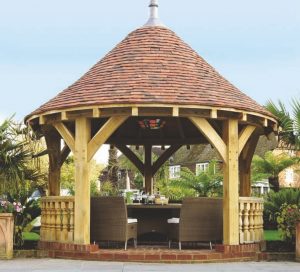

With its impressive green credentials, as well as its longevity and versatility, oak is the natural choice for many homeowners.

The mighty oak, national tree of England, is forever associated in our cultural history with strength, endurance and dependability.

With these properties, plus a rustic beauty and charm, it’s no wonder that oak wood has been a truly natural choice over centuries as a reliable and readily-available material for house-building. Originally used to construct the ‘wooden walls’ of Britain’s greatest naval ships, much of this timber was still solid enough to re-use on land when ships were dismantled after several years at sea.

It’s still in fashion, though the wood is no longer recycled from boat scrapyards! New statistics show that around 75% of self-builds are now constructed using timber, and oak frames in particular have seen a steady renaissance over the past 20 years or so.

As well as being handsome and strong, oak is eco-friendly – and this appeals to many people who choose it to build their own home, extension, garage or out-building. A reputable oak frame manufacturer (and there are several with websites) will provide a certificate to show that the timber has been sourced from a responsibly-managed forest, where every felled tree is replaced with more than one new one. Wood is said to be carbon neutral and the only organic building material.

Oak frames are usually constructed off-site by the manufacturer and then transported and erected by an experienced team. The frame is typically wrapped in a weathertight envelope which, as well as providing good insulation to meet modern building regulations, means the structure can go up neatly and quickly.

Through the wrapping, some timbers can be exposed for aesthetic reasons – simply to look good – without compromising the thermal properties. Manufacturers have worked out ingenious ways of achieving this, including using half-width secondary timbers.

It’s really important for your designer/architect to work closely with a specialist supplier who understands the way oak behaves. Green oak (unseasoned timber) is preferred by manufacturers as easier for cutting and shaping, but it will shrink after the building is complete as it continues to dry out, and this must be accommodated. Eventually the wood will be harder and stronger after the natural process. If heat is applied to speed this up, it will shock the timber into unsightly splitting. Patience will be rewarded.

Part of the appeal of oak is that it does not need finishing. Externally it will weather naturally to an attractive silver grey. Internally, in a room where the wood is likely to be splashed with water, it may be a good idea to protect it with a suitable oil.

Oak frames are generally more expensive than standard softwood frames, but you can mitigate this by mixing and matching – for example, using mainly oak in some key public areas, then echoing the theme throughout the home by using it for all lintels. You can even combine oak with steel, either seen or discreetly hidden, the metal being used simply for bolts and plates, or in large sections to help span a particularly wide space, avoiding the need for a massive piece of timber.

This traditional building material, along with contemporary engineering techniques, can combine the very best of ancient and modern to bring hearts of oak into the heart of the home.

Welsh Oak Frame – www.welshoakframe.com

Posted in: Property